We, India Biotech is eligible for advanced treatment of Ethylene Oxide Sterilization (EO-ETO) for

* Food - spice & Corn starch products

* Pharmaceutical & Ayurvedic raw materials

* Medical devices

* Serine-herbs

* Surgical products.

Ethylene oxide is a low temperature gaseous process widely used to sterilize a variety of healthcare products, such as single-use medical devices (like Stent/Balloon catheter, Anesthesia system, Nebulizer system, Oxygen therapy products etc.). Through the use of a vacuum -based process, EO sterilization can efficiently penetrate surfaces of most medical devices and its lower temperature makes it an ideal process for a wide variety of materials.

As well as Ethylene oxide gas (ETO) is widely used to sterilize materials and products that would be damaged by methods involving heat, moisture or ETO radiation. Depending on industry standards, ETO can be used to reduce or inactivate the microbial population of a product or material.

We offer subcontracting services using Ethylene Oxide (EO/ETO) method.

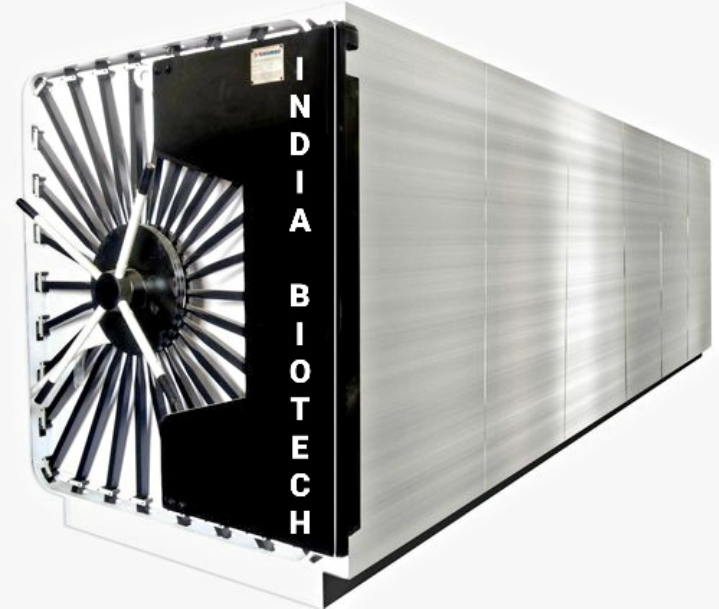

The chamber is certified to work with a maximum temperature of 55ºC. in order to optimize cycle time (and then to reduce sterilization costs), there is a degassing room for product decontamination, eliminating the EO residuals (ppm’s) inside products/boxes before they are released.

We propose contract sterilization solutions, flexible and adapted to the customer’s requirements,

ensuring the process quality and safety. INDIA BIOTECH always develops customized solutions to their clients.

A cycle validation service adapted to the product technical requirements: -